WinDCS™

Distributed Control System DNC software enables the user to organize their part programs into folders via a data base. The operator can switch between folders and standard directory operation. Machine status monitoring is also available if the customer chooses to connect the machine accordingly.

Distributed Control System DNC software enables the user to organize their part programs into folders via a data base. The operator can switch between folders and standard directory operation. Machine status monitoring is also available if the customer chooses to connect the machine accordingly.

- Distributed Numerical Control CNC-DNC Software

- CNC USB using DNC USB hardware adapters, OmniDNC

- True Client/CommServer™ DNC Network for wired and wireless DNC

- Wireless DNC, Wired DNC and RS232 DNC Systems

- Shop Folder Part Library for paperless operations

- Fully supported Remote Call Down with Redirect

- Real Time reporting of machine activity

- Multi-Level login security for users

- Capable of concurrent drip feed to all machine tools

- Show File active window to display file transfer to control

- Compatible with Greco Systems’ ActiveDNC Server,e-DNC Hub, MTIC (BTR), CNC Minifile and CNC Station

CNC Software for DNC communications

WinDNC / DCS is a true distributed numerical control CNC software system that, architecturally, is the most flexible DNC software available on the market today. Conventional DNC software, originally designed in mid 1980s, are computer bound, locking DNC communications with the client DNC software used to control the DNC network. Not so with WinDNC. The distribution of Client Software and CommServer is completely flexible. ActiveDNC Server (DNC communication engine) can be distributed anywhere throughout the shop floor environment and connected to a common local area network (LAN). This is especially valuable with very large shop floors due to machine tools being great distances apart, even perhaps in different buildings. With ActiveDNC Server distributed on different computers strategically placed, or perhaps using the e-DNC Hubs, or both, WinDNC running on one or more other PCs brings the entire DNC network together. Your DNC Network Administrator will “love” that capability. Administrative duties can be performed from his/her personal workstation or perhaps from a distant remote location.

DNC communications

CNC DNC ( Distributed Numerical Control) with RS232 DNC brings many challenges for DNC communications. CNC DNC protocol varies from one machine tool manufacturer to another, requiring the DNC systems (specifically the DNC server) to make available the specific DNC protocol for a given machine. The DNC protocol may provide sophisticated handshaking for drip feed whereby the part program is sent to the CNC control and the machine executes the part program in real time. Drip feed is specifically useful when memory is limited on the CNC control. Greco Systems believes no other supplier of CNC software has the DNC protocol library offered with WinDNC and its associated DNC server.

Distributed Numerical Control / Direct Numerical Control

DNC systems entered the industry by coupling NC/CNC machine tools to mainframe and mini-computers as far back as the early 60s. At the time, the technology was coined the term Direct Numerical Control, meaning the machine tool control was connected directly to the computer. Special hardware was built to accommodate the connection between the two devices, enabling direct numerical control. The term Distributed Numerical Control was introduced when PCs became the dominate player in the DNC network environment. Distributed meaning many PCs distributing the load of the DNC server throughout the DNC network environment. Active-DNC server provides that distributed service, enabling targeted routing of its of its DNC system and CNC machine tools.

CNC USB and DNC USB

Modern CNC controls provide CNC USB ports to enable shop floor operations to load programs from a USB Thumb Drive. The CNC USB port will typically operate in the standard fashion provided by Microsoft Windows. Greco Systems offers its e-DNC HUB and OmniDNC to provide DNC USB to early controls that do not have this built-in capability. The OmniDNC can drive up to 8 machines from a single DNC USB Thumb Drive which easily plugs into the unit.

Machine List and Machine Status

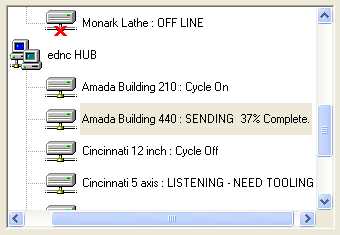

The display below shows a list of machines and the real-time status of those machines. Four machines are showing connected to “ednc HUB”, having the following conditions:

- Amada Building 210: In Cycle

- Amada Building 440: WinDNC is sending a part program to the machine.

- Cincinnati 12 inch: Out of Cycle

- Cincinnati 5 axis: “Needs Tooling” via Remote Call by the Machine operator

True Client/CommServer™ Environment

Active-DNC Server introduces true Client/CommServer environment. In this environment, WinDNC operates as a remote terminal with multiple communication host computers and hubs distributed throughout the network. In addition, multiple copies of WinDCS, operating on different computers, may also interface with the same communication host computers and hubs.

The Client/CommServer™ Advantage

There is no requirements to have a physical connection between the WinDNC operator console and the machine tool. The customer is in complete control of the physical architecture of his network. Therefore, the customer may choose to centralize control of the environment by having one or two consoles strategically placed on his network or he may decentralize by having a console at every machine tool or cell.

Part Library Folder

Part Library Folder enables the customer to organize its files from a standard directory structure in folder groups containing the information needed to produce a particular part. The operator, having the ability to examine the Part Library Folder, is given access under the part name or number to information such as Setup Sheets, Tooling Data, Traveler, Drawings and Part Programs. The Planner builds a Part Library Folder by simply dragging and dropping the required files in a Window.

Multi-Level Security

In addition to the security adopted for the Local Area Network (LAN) environment, WinDNC employs multi-level security as it applies to DNC Administrators, Operators and Machine Tools. An operator can be restricted to a single machine or given access to any number of machines on the network. Administrators are given access to communication setup parameters as it applies to machine tools.

Machine Tool Monitoring

WinDNC has the capability of showing real-time status of machine tools on the shop floor. An Opto-isolated monitor/modem is available from Greco Systems that can be installed in the machine control to monitor one or more digital points. The state of the machine is monitored in real-time by an e-DNC Hub and made available on the PCs connected to the network running WinDNC or e-DNC Explorer. Connecting directly to the machine to pick up digital points will require some exploratory engineering and to make discrete connections to the machine. Therefore, we recommend consulting with Greco Systems’ Technical Support personnel before attempting to hook up machines for monitoring. Greco also utilizes partners that will go to your facility and perform the installation.

Remote Call

Remote Call is a feature that enables the Machine Operator to invoke upload and download of part programs at the machine control. A part program is identified by its file name on the server. Directory information can also be obtained using Remote Call. This feature eliminates the need for a separate PC or terminal for the operator to call up part programs. Although WinDNC does not need to be running for remote call functions, it will display the status of that activity.

Text Messaging

Text Messaging is an enhanced feature of Remote Call. The operator is given the ability to transmit a short text message in order to notify other departments or supervisors of issues relating to his machine or job. The message is displayed on all of the PCs running WinDNC and given access rights to those machines. Messages such as MACHINE DOWN or TOOLING NEEDED would help expedite recovery in getting a machine back into production.

Compatible with Greco Systems’ Devices

The WinDNC is compatible with Greco Systems hardware devices, including the MTIC (BTR), CNC Minifile, CNC Station and other Greco Box devices. These devices are designed to enhance the capability of older machine tools with provisions for connecting to a DNC environment.

Touch Screen Computer Friendly

WinDNC operator’s screen is touch screen computer friendly. Large buttons enable the operator to easily navigate and initiate the functions needed to control DNC operation. There are no double-clicks required and, although rare, an on-screen keyboard appears when needed to enter text information.