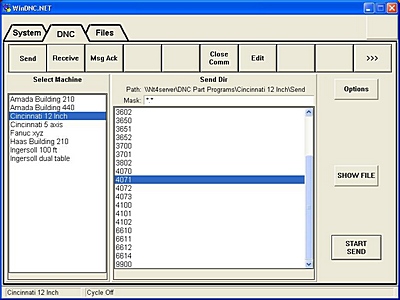

WinDNC™

DNC software operator console, simple to learn, ideal for touch panel computer as well as keyboard and mouse operation. WinDNC is Greco Systems legacy Microsoft Windows DNC software. It is compatible with Greco DNC Hub, BTR (MTIC), CNC Minifile, CNC Station and Touch Screen Computer.

- Platforms Windows 11, 10, 8, 7 and Windows Servers

- Machine Tool Configuration administrative tools

- Sending and Receiving NC Programs with or without drip feed

- Remote Call from the CNC Control

- Invoke DNC operations with Smartphone, Tablet or PC

- Part programs managed locally or server share

- Hardwired DNC, Wireless 802.11 b/g/n or both

AUTOMATE PART PROGRAMS

WinDNC is a very stable Windows-based product, originally developed in the early 90’s, which provides an automated method for the storage and transfer of NC part programs. WinDNC is designed with an easily understood “point and pick” user interface which enables machine operators to quickly master the software. The selection of machine and program names from a pre-defined list will prevent data entry errors and improve efficiency.

SUPERVISOR FUNCTIONS

The supervisor screen is menu-driven and displays both current and historical communication activity to all machine controls. Menu selections are made with a single keystroke or pointing device such as a mouse. The supervisor can perform basic file management tasks and configure machine tool communication parameters and also set upload or download paths for each machine tool.

MULTITASKING OPERATIONS

Sharing resources with multiple software applications reduces the hardware required in the shop which reduces initial capital investment and maintenance expenses. Using multitasking software, such as Windows, the WinDNC workstation enables multiple applications to run concurrently with WinDNC software.

MACHINE TOOL CONFIGURATION

Configuring WinDNC software to communicate with each machine control or Greco Systems’ interface device on the network is accomplished through an easy to use menu-driven screen at initial network commissioning. This allows for the many differences in machine tool protocols, baud rates, and other unique communication parameters. Separate directories may be assigned for uploading and downloading to each machine control.

OPERATOR FUNCTIONS

The machine operator interface is menu-driven and displays all available functions from a single screen. Menu selections are made with single keystrokes or a pointing device, such as a fingertip or mouse. The WinDNC software was specifically designed to be compatible with a touch screen computer. Other functions available to the machine operator include the transfer of NC part programs to the machine control.

SENDING OR RECEIVING NC PROGRAMS

WinDNC is capable of the continuous downloading of NC part programs to machine controls which can receive data in tape or DNC mode. The machine operator may initiate uploading and downloading of NC part programs directly from the machine control.

CONNECTING TOOL PRE-SETTERS

Tooling offsets from many popular tool pre-setters can be transferred directly to machine tool controls on Greco Systems networks. Many CMM’s (Coordinate Measuring Machines) are also capable of communicating with WinDNC software.

REMOTE CALL DOWN

A remote request allows the machinist on the shop floor to send and receive CNC programs directly from their CNC controls. No more need to walk back and forth from CNC machine to PC.

UPLOAD AND DOWNLOAD DIRECTORIES

The machine configuration screen permits the supervisor to assign a unique upload and download directory path for each machine control. Machines that run the same programs may share common directories.

IMPROVE EFFICIENCY

WinDNC is the easy to use solution to operating multiple machines simultaneously via the Windows format to improve shop efficiency.